Historic, Rare, and Unwanted

For almost three years, up to the summer of 2017, I owned and maintained one of the most obscure models of the Volkswagen lineage. As the headline suggests, it was the Dasher. Although it is a very special car to myself, and to history, it hasn’t built a long-standing position with auto collectors.

Well into the age of modern cars, VW and Porsche famously built air-cooled engines mounted in the rear of the vehicle. In 1974, facing new air pollution and fuel economy standards, they finally entered the modern age. They attempted to make a splash with a new fleet of front mounted water-cooled engines, and a fresh look.

Industrial designer Giorgetto Giugiaro was commissioned for the modern VW fleet. He had established himself for decades with designs for Ferrari, Maserati, Alfa Romeo, BMW, and more, and was named in 1999 as “Car Designer of the Century” by the Global Automotive Elections Foundation. The Dasher may be counted among his less celebrated work, along with the Delorean, aka the time machine from Back to the Future.

Engineering crucially came from the original Audi team, sharing systems with the Audi 80. This is where it gets interesting. The first Audi 80 was given a facelift by Giugiaro then rebranded for American markets as the Fox. Similarly, the VW Dasher was actually the Passat, in Europe. And finally, they all shared high-performance components with Porsche.

I didn’t know until I became a VW owner that Audi, Porsche, and VW were one massive automaker. This American branded Dasher was supposed to be the family’s perfect car, combining the luxury of the Audi with the sportiness of the Porsche with the economy of the Volkswagen.

The 1977 Dasher coupe and the Porsche 924 were essentially the same car: Both had in-line 4-cylinder motors mounted at 45-degrees with Bosch mechanical fuel injection, fastback design with adequate interiors to fit five passengers. Naturally, the Porsche had a stronger motor (2.0L versus 1.6L) while sharing the same four speed manual transmission. My Dasher was a fake sports car. It sounded like one, it felt like one, but it was still a VW.

Getting It Started

A good friend, Tony, gave me the car because it wasn’t starting, and it had been breaking down all the time, and after years of inaction, the interiors were beginning to mold.

When you have a car that isn’t starting, you have to investigate the problem from three pillars: Air, Spark, and Fuel. If it is cranking, as mine was, but not combusting, then it can be a lot of things. Air blockages can be visually inspected without the car running. I found an old and moldy air filter and a few weak connections in the vacuum lines. Handled those first.

The battery needed to be charged and good enough to crank over the engine to deliver enough current to activate the spark plugs, to ignite fuel at the combustion chamber. You need solid main power and main ground connections. After charging up, cleaning connections, and installing new plugs and wires, no change. I was really taking shots in the dark. After all this I realized that the electric fuel pump wasn’t switching on.

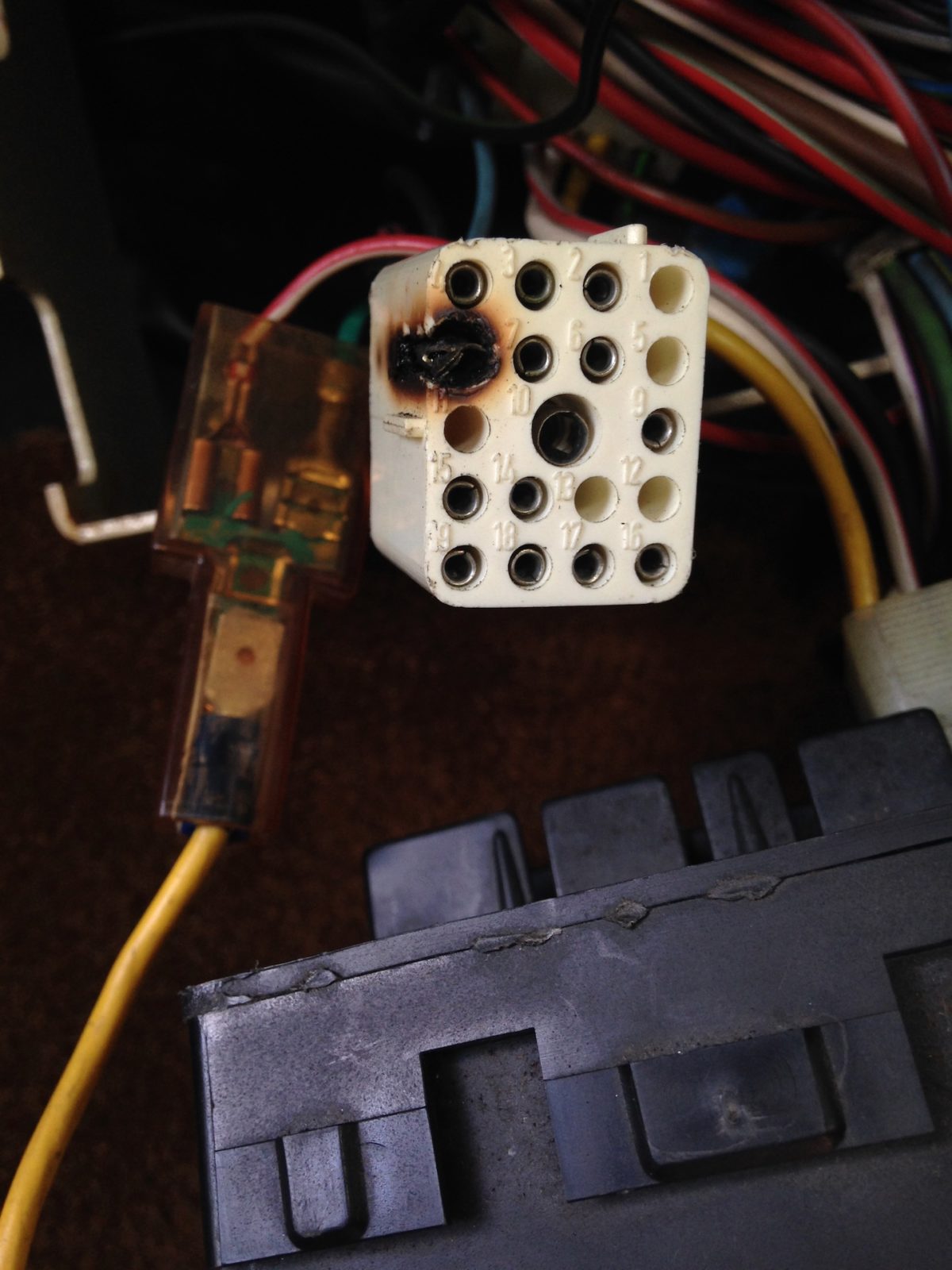

It turned out that Volkswagen had a recall on this model for its overheating fuel pump circuit. The circuit inside the fuse panel had gone resistive, meaning it would not pass current. I had to bypass it to get the fuel pump to operate without its relay system. Not ideal, but it repaired the problem, and by adding an in-line fuse, it was safe enough to operate. I also went to the junk yard and pulled fuel injection parts from a Porsche 924. And of course a new fuel filter.

This Porsche has seen better days, but its parts were plentiful.

Found this guy in the junk yard, pulled its fuel injection parts.

I discovered this early on: Fuel pump circuit overheated. This was probably a gradual thing. Owner may have never responded to the recall put out for this problem, by VW.

This is where I worked on it through its first phase of maintenance.

When I was sure that fuel was working itself through the system and air was sufficient, I thought it would start. But not yet. At least now I could focus on spark. Without it running, I was continuously charging the battery because cranking the engine draws tons of energy and I still hadn’t isolated the problem.

I soon gave up and soft towed it down the street to a VW garage using my van. A fellow named Marcel got it running just like that, in the street, didn’t charge me. Turned out I didn’t know a thing about ignition points. I had dealt with distributors before, but points are old school timing mechanisms, and they need to be perfectly gapped to run the ignition system.

The struggle wasn’t yet over. There were still plenty of issues to address, but I had it running.

Read the personal memoire about this experience here.

The Rebuild

That is only the saga of getting it running. From then until summer 2017, before I sold it to another Dasher lover in Idaho, I was constantly catching up with maintenance, even whilst getting ahead of maintenance.

I noticed it was losing performance after about a year, struggling up hills more than it used to, using more fuel. Then suddenly, one day I went to drive it and it would not start. It cranked and cranked. I ran a compression test and found its pressure levels were below specification. That means one thing: crap motor.

Rebuilding the engine in my situation was not ideal. I pulled the motor at the barn in which I was living, using a “cherry picker” hoist. I picked up Doug in Tony’s truck, brought him to the barn, and after pulling it, loaded it into Tony’s truck, then delivered it to Doug’s warehouse. I had to commute to Doug’s place and put in a few hours of work a day, ordering all the parts online. This extended the length of the whole project with every small hiccup.

I’m replacing tie rods inside the motor compartment that has been thoroughly gutted.

At the barn, dropping the motor in place.

Preparing each piston for installation.

To prevent damage to our honed combustion chambers, we lubricate. Motor oil take moments to work its way through the system.

I’m carefully installing the bearing caps.

When Doug and I tore it down at his garage, we did not discover any damage that should have stopped it from running. Sure, you could spot a little wear, but all the rings, bearings, pistons, valves were intact, the crankshaft was not pitted, or camshaft, and we didn’t have to bore down the cylinders. Doug has rudimentary machining equipment for the minor issues. I got lucky.

Before and after this, I was plagued with electrical issues, I was always ringing out towels to keep the interiors dry, I was constantly trying to get emissions right without losing performance (and there was no way it could pass Oregon regulations without being leaned to hell). I mean it was annoying, this car. For some reason, I loved it.

I made it halfway to a complete restoration with this car, in the two and a half years I drove it. I rebuilt the motor, replaced almost all brake system components, alternator, starter, battery, steering, tie rods, ball joints, car stereo, throttle and clutch cables, belts, and more. I would have moved onto interiors, but I was constantly handling mechanical or electrical problems. It was just the most rational thing to sell it to a collector, take it out of daily driving.

I’m glad I got back what I put into it, financially. I needed a car, it got me to my jobs, earning my living. Maintenance costs what it costs. It was always turning heads on the street. It was fun to drive, and I learned so much about auto-mechanical engineering that I can tackle a project like this again knowing what to expect.

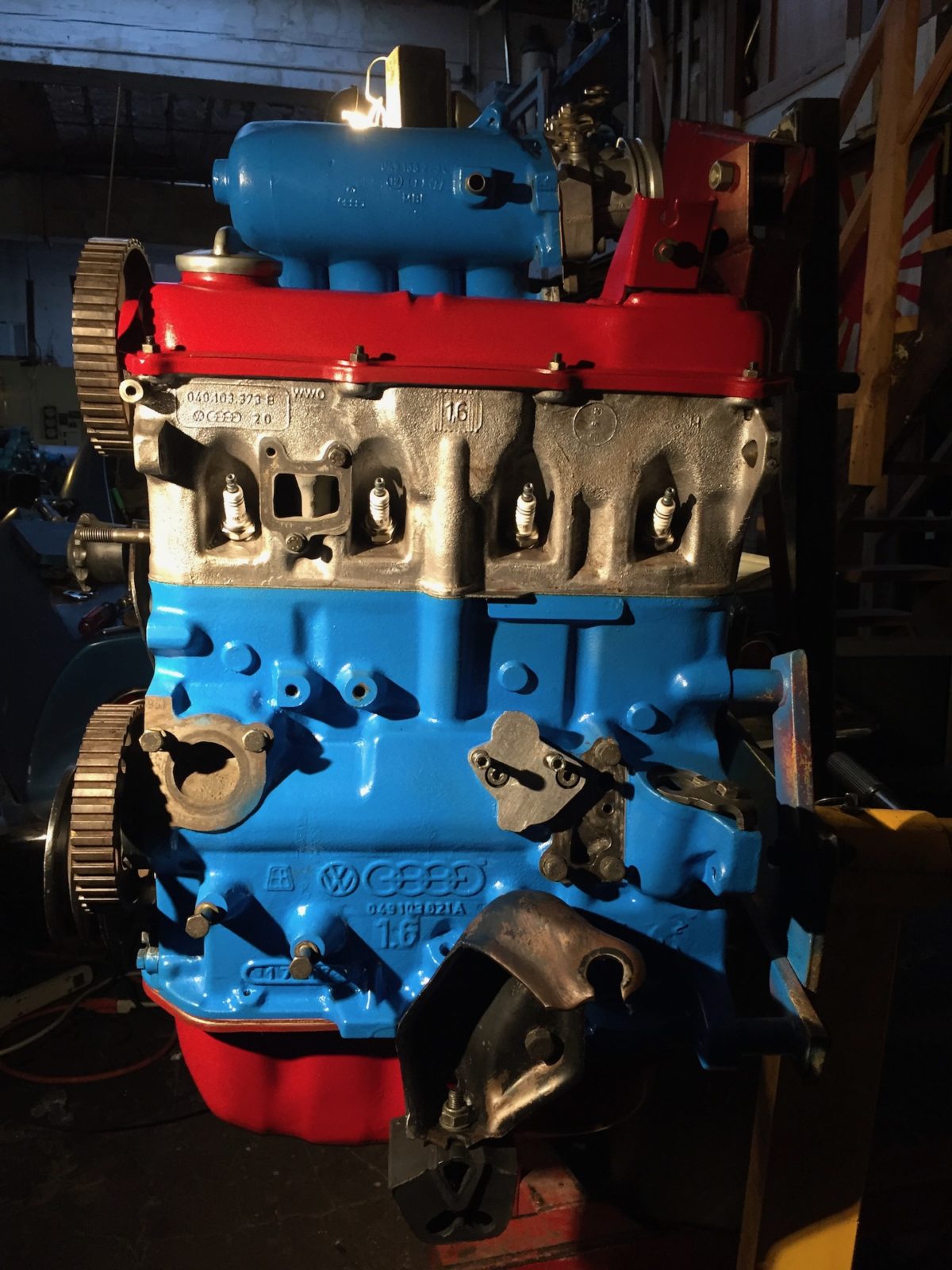

On this side, you see the spark plugs and mounts for the distributor, fuel pressure regulator, and water pump. Top to bottom: valve cover red, head unpainted, block blue, oil pan red.

The whole motor before service

It is difficult to describe how much pride one has for taking an old motor and making it look fresh.

Almost all the components here are new, or inspected and serviced.